Introduction to Annular Cutter ( Mag Drill Bits )

An Annular Cutter, with a center free annulus bell shape, is used to make holes in metal. It is also known as mag drill bits which is named after the use in magnetic drilling machine. Usually, annular cutters are available in Tungsten Carbide Tipped (TCT) and High Speed Steel (HSS).

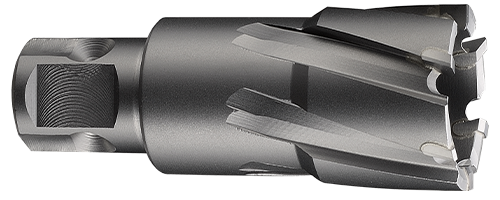

Tungsten Carbide Tipped (TCT) Annular Cutter

T.C.T annular cutter also called tct broach cutter or tct core drill,tct core bit, tct hole saw. tct means tungsten carbide tipped. which cutting teeth is carbide tips brazed, usually thinking as the replacement or upgrade of hss annular cutter. Tungsten carbide is sharper than most materials and about 2 times harder than steel. It is a new type of drilling tools, which support magnetic drill.

T.C.T also has hot hardness at high temperatures allowing faster drilling speed. Besides, tungsten carbide has a very high wear resistance and its thermal expansion is less than steel. Due to the T.C.T cutting edge, the annular cutter can drill hard materials with a high quality performance.

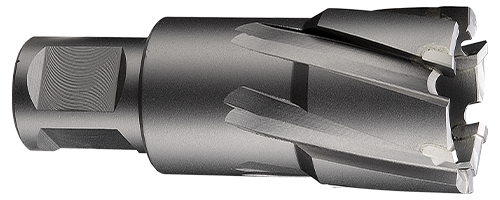

High Speed Steel (HSS) Annular Cutter

High Speed Steel (HSS) is a kind of high alloy tool steel with more alloying elements such as W, Mo, Cr and V added.

According to different applications, H.S.S can be divided into general-purpose high-speed steel and high-performance high-speed steel. H.S.S can withstand higher temperatures and keep its hardness to drill faster than carbon steel, like the name of high speed steel. Mostly, the H.S.S annular cutter is made from M2 steel. In order to drill harder materials, cobalt will be added to steel to make M42 type H.S.S annular cutters.

High speed steel cutting tools have excellent comprehensive properties in terms of strength, toughness and processability. In complex tools, especially for the manufacture of hole processing tools, milling cutters, threading tools, broaches, gear cutting tools and other complex cutting tools, high-speed steel still occupies a major position.

High speed steel knives are easy to sharpen cutting edges. If the cutter becomes blunt, it can be re-sharpened to use again.

Hollow Core Design

The hollow core design provides the annular cutter an efficient and quick way to make holes in metal. Core bit is a new type of drilling tools, which support magnetic drill block, the large steel components can be anywhere drilling, efficiency is twist drill-10 times.

Compared with conventional drill bits, annular cutters only contact with the metal by the outer perimeter to cut the periphery of the hole, instead of removing the whole area of the hole, and leave a solid slug with less chips.

Flute

During the cutting process, the heat from drilling will transfer to chips and cause chips to expand which may result in a stuck annular cutter in the hole. The design of flute can lead the chips out of the hole smoothly to avoid overheating and jammed.

Shank Type

You can use an adapter (from Weldon to your shank type) for the annular cutter to fit different Magnetic Drilling Machines.